Metal Injection Moulding

Chinatech Sourcing Ltd are specialists in the Metal Injection Molding (MIM) process and have a working partnership with 2 factories in China. Some of the benefits of dealing with Chinatech Sourcing Ltd:

- We can often provide tooling at a fraction of the cost of European sourced parts. (Typically 50%)

- We can often support lower volumes and batch quantities compared to our competitors

- With technical specialists based in the UK and China, we can provide fast and expert feedback on design feasibility and DFM for your components

About Metal Injection Moulding

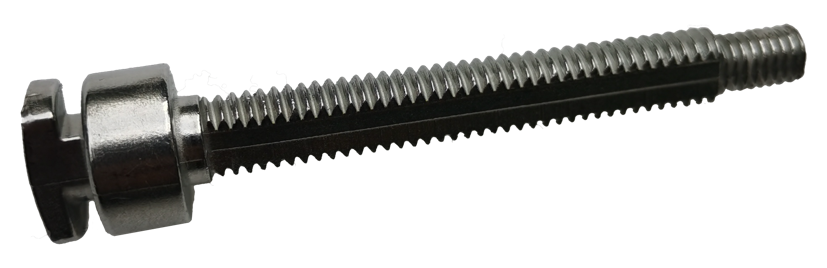

Metal Injection Molding (MIM) is an advanced metal forming process that allows complex parts to be shaped in a single operation and in high volume – a perfect solution for creating small, complex metal components. Although metal injection molding can be utilized across a wide range of components, the best applications are typically small in overall size and less than 100 grams in weight. It is sometimes referred to as Powder Injection Molding (PIM).

Key MIM Differentiators:

- Costs less than CNC

- Produces better feature detail than investment casting

- Provides very accurate results

- High complexity shape capability

- More efficient use of material and processes

- Less material waste

- Repeatability

- Excellent mechanical properties

- Lower overall product cost

- Tailored solutions using unique materials

- Materials can be brazed/joined to a variety of components for complete assembly solutions

- Works great for simple and complex metal parts formed to tight tolerances

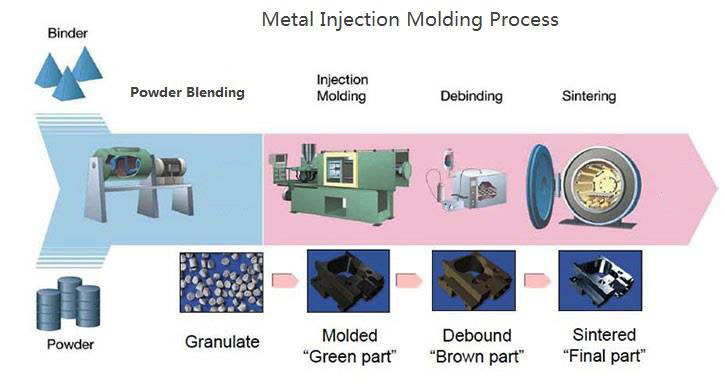

MIM Process

To create MIM parts, there are 5 basic steps.

MIM Parts Alloy Capabilities

- Stainless Steel

- Low-Alloy Steel

- Super-Alloys

- Controlled Expansion Alloys

- High-Density Alloys

- Soft Magnetic Alloys

MIM materials include all standard alloys, plus application-specific alloys upon request.

MIM Tolerances

| NOMINAL DIMENSION (mm) | TOLERANCE +/- (mm) |

|---|---|

| < 3 | 0,05 |

| 3 - 6 | 0,06 |

| 6 - 15 | 0,075 |

| 15 - 50 | 0,15 |

| 30 - 60 | 0,25 |

| > 60 | +/- 0,05% * |

| STRAIGHTNESS PARALLELITY LEVELNESS | 0,5% OF THE LONGEST DIMENSION |

|---|---|

| Angle | +/- 0° 30' |

| Radii | +/- 0,3 mm |

| Surface roughness | Rz 8 - 12 |

While the normal dimensional tolerance with MIM process is +/- 0,5% of the normal linear dimensions, the deviation can be reduced to +/- 0.3% through deliberate process control. Even tighter tolerances will be realized by secondary operations such as CNC machining and grinding.