Plastic Injection Moulding

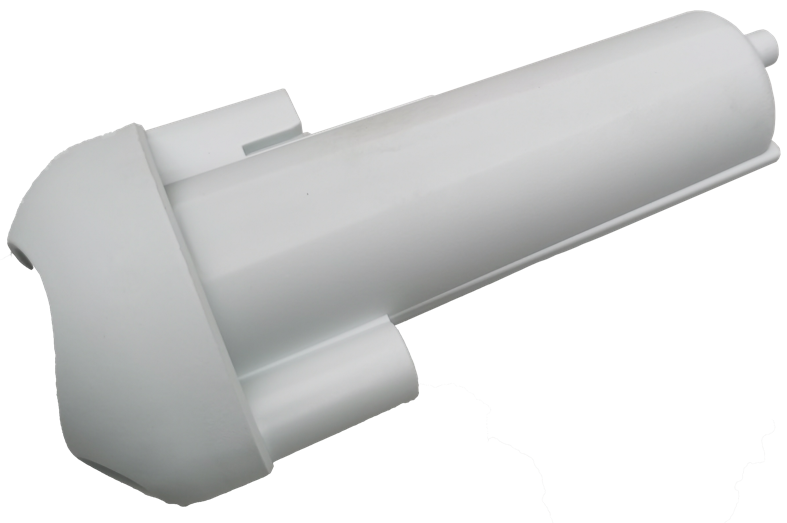

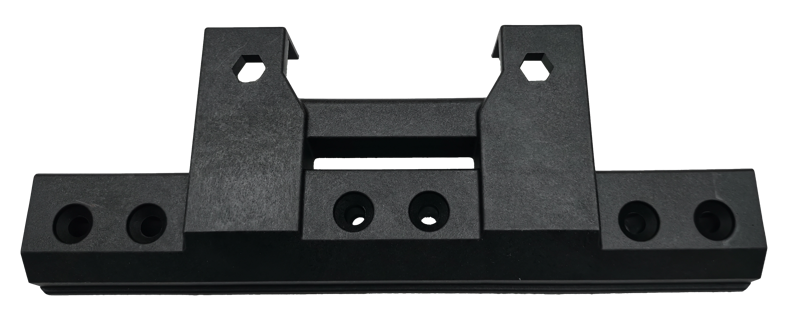

Plastic injection moulding is the process of melting plastic pellets (thermosetting/thermoplastic polymers) that once malleable enough, are injected at pressure into a mould cavity, which fills and solidifies to produce the final product.

Chinatech Sourcing Ltd are specialists in the plastic injection moulding process and work with a number of world class partner organizations in the far east to supply small and large plastic moldings. Some of the benefits of dealing with Chinatech Sourcing Ltd are:

- We can often provide tooling at a fraction of the cost of European sourced parts. (Typically 50%)

- We can often support lower volumes and batch quantities compared to our competitors

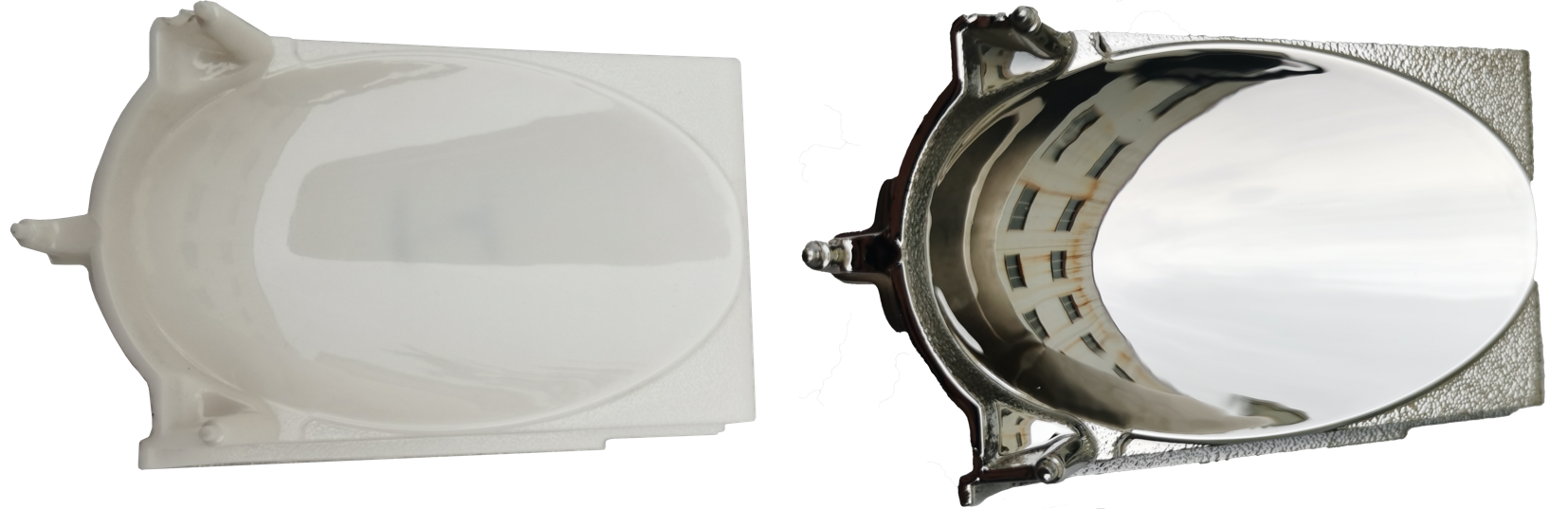

- Sometimes plastic moldings can require further post processing including metalising (reflective finish) or assembling and packing into presentation packing. These additional processes can be expensive, but we can often help you benefit from the lower costs associated with China manufacturing.

- With technical specialists based in the UK and China, we can provide fast and expert feedback on design feasibility and DFM for your components

We provide quality mouldings with customer specified surface finishes from polished to

spark finishes (VDI 3400) and over moulding options for “soft touch” feel parts.

See our Case Studies page for examples of some of our work.

For advice regarding tolerances draft angles etc, please download our Design Guide.

Thermoplastic Materials

Table of properties:

| Abbreviation | Full Name | Properties | Applications |

|---|---|---|---|

| ABS | Acrylonitrile Butadiene Styrene | Tough, opaque, rigid, hard, high gloss | Automotive, office machines, domestic appliances, refrigeration, pipe fittings |

| ASA | Acrylonitrile Styrene Acrylonitrile | Rigid, transparent, tougher alternative to Styrene | Automotive, telephones, traffic signs, electric fan components, wash basins |

| BDS | Butadiene Styrene Block Copolymer (See also SBC/SBS) | Tough, crystal clear | Medical products, drawing instruments |

| EVA | Ethylene Vinyl Acetate Copolymer | Tough, semi-opaque, flexible, good low temperature properties | Food packaging, surgical products, ice cube trays, bicycle saddles |

| HDPE (PE-HD) | High Density Polyethylene | Tough, semi-rigid, translucent, excellent weatherability/chemical resistance | Containers, bottle crates, food storage boxes, housewares, dustbins, pipe fittings |

| HIPS | High Impact Polystyrene | Rigid, hard, translucent | Household appliances, toys, disposable cups, toilet seats |

| LCP | Liquid Crystal Polymer | High stiffness, excellent stability at high temperatures | Precision parts, stainless steel and ceramic repalecement, electrical connectors, surgical instruments, dental tools |

| LDPE (PE-LD) | Low Density Polyethylene | Flexible, translucent, durable, good weatherability/low temperature performance, excellent chemical resistance | Lids and closures, containers, bins, laundry baskets |

| LLDPE | Linear Low Density Polyethylene | Stronger and tougher than LDPE, better mechanical properties at low and high temperatures | Closures, screw caps, cold room containers, high quality housewares, toys |

| MDPE (PE-MD) | Medium Density Polyethylene | Fits midway between High and Low Density Polyethylene | Containers, closures, pipe fittings |

| PA | Polyamide (Nylon) | ||

| PA6 | Polyamide 6 (Nylon 6) | Rigid, tough, translucent, resistance to oils, good dialectric resistance, hard wearing | Gears, bearings, bushes |

| PA11 | Polyamide 11 (Nylon 11) | As for Nylon 6 but better performance over wider range of temperatures | Cable ties, aircraft battery cases, sports equipment |

| PA12 | Polyamide 12 (Nylon 12) | ||

| PA46 | Polyamide 46 (Nylon 46) | ||

| PA66 | Polyamide 66 (Nylon 66) | Higher impact strength and better low temperature properties than Nylon 6 | Automotive fans, door handles and filters, kitchen appliance housings |

| PAA6 | Polyarylamide | High rigidity, excellent strength, high temperature performance comparable to metals | Automotive under bonnet components and door handles, electric motor housings, furniture |

| PBT | Polybutylene Terephthalate | Rigid, extremely tough, clear, wide operating temperature range | Automotive windscreen wiper arms and door handles, electronic parts, household appliances |

| PC | Polycarbonate | Rigid, tough, excellent impact resistance, good weatherability and dimensional stability | Medical, glazing, lighting, CDs/DVDs, spectacles, safety helmets, automotive light covers and clear roof panels |

| PC/ABS | Polycarbonate/ABS blend | Combination of PC and ABS properties | Similar applications to ABS but where greater toughness required |

| PE | Polyethylene | ||

| PEEK | Polyether Etherketone | Outstanding stability at wide temperature range, high cost, specialist | Chemotherapy devices, surgical tools, microwave grills |

| PEI | Polyetherimide | High strength, excellent flame and heat resistance | Medical devices, electrical insulators, pharmaceutical process equipment |

| PET | Polyethylene Terephthalate | Tough, good impact strength, clear, good high temperature performance | Blow moulded bottles |

| PES | Polyethersulphone | Tough, wide operating temperature, self-extinguishing | Microwave grills and dishes, medical respirators, dental reamers |

| PMMA | Polymethyl Methacrylate (Acrylic) | Hard, rigid, crystal clear, good weatherability | Lenses. Lighting covers (indoor and outdoor), automotive rear light lenses |

| POM | Polyoxymethylene (Acetal)(Polyformaldehyde) | Rigid, very tough, translucent, good dimensional stability and electrical properties | Gears, bearings, electric kettles, plumbing fittings, valve and pump housings, automotive fuel systems |

| POM-H | Acetal Homopolymer | Higher rigidity and resistance to fatigue than copolymers | |

| POM-K | Acetal Copolymer | Better resistance to hot water and alkalis and better long term temperature properties than homopolymers | |

| PP | Polypropylene | Semi rigid, translucent, excellent chemical resistance, good recyclability | Crates and bins, housewares, washing machine drums, plumbing fittings, kettle bodies, automotive bumpers and dashboards |

| PPE | Polyphenylene Ether | See PPO | |

| PPO | Polyphenylene Oxide (usually modified – PPO-M) | Rigid, tough, opaque, wide operating temperature, excellent dialectric properties, may be self extinguishing | Washing machine, dishwasher and pump components, electrical and automotive components |

| PPS | Polyphenylene Sulphide | Rigid, tough, high temperature resistance (continuous use up to 240C), good mechanical and insulation properties | Often used as aluminium replacement, connectors, terminal blocks, sockets, coil formers, relay components, automotive ignition parts |

| PPVC (PVC-P) | Plasticised Polyvinyl Chloride | Flexible, strong, high abrasion resistance, good weathering properties | Footwear, garden hoses, electric cable insulation |

| PS (GPPS) | Polystyrene | Rigid, high gloss and transparency, brittle | Toys, disposable tumblers, containers |

| PSU | Polysulphone | Tough, wide operating temperature, self-extinguishing, amber colour | Microwave grills and dishes, dental reamers, dialysis equipment, stainless steel and glass replacement for milk collection equipment |

| PVC | Polyvinyl Chloride | ||

| PVDF | Polyvinylidene Flouride | Strong, tough, excellent chemical and heat resistance and UV stability, translucent milky white | Valves, pumps and bearings, mainly in the chemical process industries |

| SAN | Styrene Acrylonitrile Coplymer | Rigid, tough, transparent, resistant to oils and greases | Automotive real lamp covers and reflectors, refrigerator doors and trays, washing machine trims and windows, quality kitchen utensils |

| UPVC (PVC-U) | Unplasticised Polyvinyl Chloride | Rigid, tough, good weatherability, flame retardant, usually clear | Replacement windows and doors, pipes and fittings, rainwater goods and bottles |

| PP-EPDM | Rubber Modified/Reinforced Polypropylene | Tough, flexible, off-white | Automotive bumpers and door protection strips |

| SBC/SBS | Styrene Butadiene Styrene Block Coplymer | Tough, less brittle than GPPS, crystal clear | Centrifuge tubes, medical bottles and mouth tubes, pens and drawing instruments |

| TPE | Thermoplastic Elastomer (Rubber) | Flexible, good low temperature properties Rubber replacement, automotive gaiters, seals and gaskets. | Used for overmoulding to provide ‘soft-touch’. |

| TP-EE | Thermoplastic Elastomer – Ether Ester | ||

| TPR | Thermoplastic Rubber (Elastomer) | ||

| TPV | Thermoplastic Elastomer or Rubber – Crosslinked | ||

| TPU | Thermoplastic Polyurethane | Range from hard and rigid to soft and flexible, better abrasion and tear resistance than rubber, excellent weatherability and UV resistance | Bellows, diaphragms, gaskets and seals, machinery mounts, shoe soles and heels. Overmoulding, especially in automotive interiors |